All Metal Finishing Solutions are easy to use, produce authentic, consistent results, require no heat or electricity, are water based, nonflammable and react within minutes. Achieve a wide variety of antiqued and colored finishes on metal.

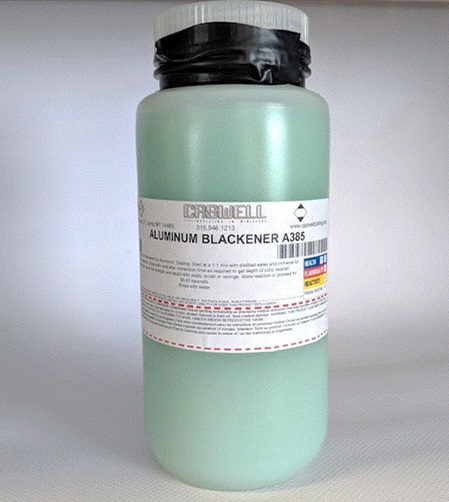

Aluminum Blackener A385

An immersion or swab-on finish at room temperature for aluminum surfaces. Mild acidic liquid concentrate used full strength for swab-on finishing and touchup finishing or diluted with 4 parts water for immersion finishing. Frequently used to produce an imitation pewter finish on aluminum surfaces. A-385 can be used to give aluminum and its alloys a decorative gray-to-black finish without the use of professional equipment or precautions.

|

Use A-385 to:

- Blacken aluminum and its alloys at room temperature

- Eliminate need for special equipment, safety/control procedures, ventilation, and heating

- Achieve pewter gray to deep black finishes, depending on dilution and immersion time

- Use as an immersion solution (when diluted)

- Use as a swab-on solution (when used at full strength)

- Achieve minimal thickness and no dimensional change

- Avoid caustic fumes, unpleasant odors, and safety hazards

IMMERSION FINISHING PROCEDURE

1.) Clean, The aluminum surfaces to be finished must be free of oils and other soils as well as free of oxides prior to blackening and they may be removed either mechanically or chemically.

2.) Rinse for a minimum of 30 seconds in a bottom-fed overflowing cold water rinse tank to remove residual blasting dust or cleaning solutions.

3.) Blacken

Step 3a. Prior to charging a production tank, some experimentation should be performed with properly prepared sample parts. Use various dilutions of A-385 concentrate at 1-5 parts water, and different immersion times to determine the conditions and parameters required to produce the desired depth of black.

Step 3b. As a starting point, dilute 1 part A-385 with 1 part water. Determine by test the shortest immersion time necessary to produce the desired finish—usually 30-90 seconds. Vary the amount of water to test for shortest immersion time.

4.) Rinse for a minimum of 30 seconds in a bottom-fed overflowing cold water rinse tank to remove residual blasting dust or cleaning solutions.

Repeat steps 3-4 if more blackening is needed.

5.) Seal or lacquer for added richness and abrasion resistance.

SWAB-ON, TOUCH UP TECHNIQUES

1. Clean and deoxidize the surfaces in one of the ways mentioned above. Abrasive paper or steel wool may be used to deoxidize small areas.

2. Rinse the area thoroughly with water.

3. Apply full strength Insta-Blak A-385 generously with a swab, brush or sponge. Allow the blackening reaction to proceed for 30 to 90 seconds.

4. Rinse area with running water or sponge area with a damp sponge. Hot water will accelerate drying.

5. Air dry or wipe dry.

6. Buff with a cloth or brush to remove any adhering, powdery spent chemicals.

7. Repeat steps 3, 4, 5 & 6 if a darker finish is desired.

8. Seal or lacquer for added richness and abrasion resistance.